In the world of modern construction, material selection is a crucial decision that directly impacts the strength, durability, cost, and performance of a building or infrastructure. Among the most commonly compared materials are stainless steel and aluminum. Both are known for their versatility and widespread use across residential, commercial, and industrial projects.

But when it comes to Stainless Steel vs Aluminum, which material truly stands out in the construction industry?

This article provides an in-depth comparison between stainless steel and aluminum, exploring their physical properties, costs, advantages, disadvantages, and ideal use cases in construction.

Read more about: How Stainless Steel Improves Efficiency in the Medical Industry

1. Strength and Durability

Stainless Steel:

Stainless steel is renowned for its superior strength and durability. It can handle high loads and is resistant to deformation under stress. This makes it ideal for:

Structural frameworks

Load-bearing beams

High-rise buildings

Bridges and heavy-duty construction

Its durability also extends to resistance against wear, impact, and environmental degradation, making it suitable for long-term infrastructure.

Aluminum:

While aluminum is lighter than stainless steel, it offers less tensile strength. It’s often used where weight reduction is essential but doesn’t need to support massive loads.

Typical uses include:

Window frames

Roofing sheets

Cladding panels

Temporary scaffolding structures

Though aluminum can be reinforced with alloys, it generally falls short in applications requiring extreme structural integrity.

Winner in strength and durability: Stainless Steel

2. Weight and Flexibility

Aluminum:

One of aluminum’s biggest advantages is its lightweight nature — about one-third the weight of stainless steel. This makes it easier to transport, lift, and install.

In addition, aluminum is more malleable and flexible, allowing for easy shaping into custom forms, which is beneficial in architectural designs and facades.

Stainless Steel:

Although significantly heavier, stainless steel is still formable but requires more effort and specialized tools to bend or cut. Its weight can lead to higher transport and installation costs.

Winner in weight and flexibility: Aluminum

3. Corrosion Resistance

Stainless Steel:

Stainless steel is highly resistant to rust and corrosion, especially in grades like 304 and 316. Grade 316, in particular, is suited for marine environments or construction near salty or humid areas.

With proper maintenance, stainless steel can last decades without corrosion, making it ideal for exposed structures.

Aluminum:

Aluminum also resists corrosion thanks to its natural oxide layer, which prevents rusting. However, it is more vulnerable to galvanic corrosion when in contact with other metals, especially in marine or industrial environments.

Winner in harsh environments: Stainless Steel

4. Cost Comparison

Stainless Steel:

Stainless steel is typically more expensive due to its density, higher manufacturing cost, and added alloying elements like chromium and nickel.

Initial material cost + fabrication cost = higher investment.

Aluminum:

Aluminum is generally more affordable, especially for non-load-bearing or decorative applications. Lower weight also reduces shipping and handling costs.

Winner in affordability: Aluminum

5. Maintenance and Longevity

Stainless Steel:

Known for its low maintenance, stainless steel doesn’t need painting or protective coating. It remains visually appealing and structurally sound with minimal care.

Its long life cycle reduces the need for frequent replacements, making it a cost-effective choice over time.

Aluminum:

Aluminum may require protective finishes like anodizing or powder coating to maintain its appearance and extend lifespan, especially in demanding environments.

Winner in longevity and maintenance: Stainless Steel

6. Environmental Impact and Recyclability

Both stainless steel and aluminum are 100% recyclable, which is a major plus in sustainable construction.

However, the energy required to produce aluminum from raw materials is significantly higher than that for stainless steel. Despite this, aluminum recycling uses only about 5% of the energy compared to its initial production.

Winner in sustainability: Tie

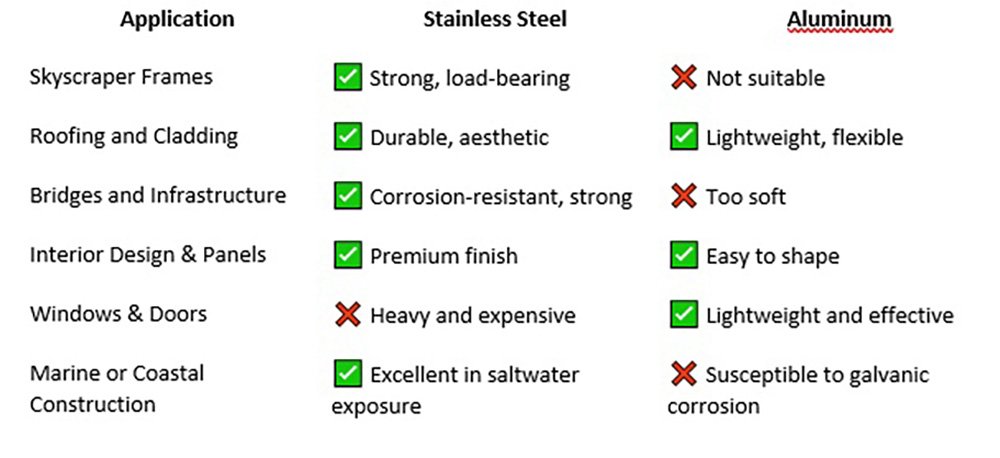

7. Applications in Construction

8. Aesthetic Appeal

Stainless Steel:

Stainless steel offers a sleek, modern, and polished finish that maintains its luster for decades. It is often used in high-end architectural features where aesthetics and prestige matter.

Aluminum:

Aluminum also provides a clean, modern look, and it can be anodized in various colors. It is often favored in contemporary building designs.

Winner in luxury appeal: Stainless Steel

Winner in color variety and customization: Aluminum

Final Verdict: Which is Better?

The answer to the Stainless Steel vs Aluminum debate depends entirely on your project requirements. If strength, corrosion resistance, and longevity are your top priorities — go with stainless steel. If lightweight, flexibility, and lower costs are more important — aluminum may be the smarter choice.

Both materials bring unique strengths to the construction table, and in many modern projects, they are used together to achieve the best combination of performance and efficiency.

Read more about: Why Stainless Steel is Widely Used in the Food Industry