Stainless steel is one of the most versatile and widely used materials in modern industry. Its corrosion resistance, strength, and aesthetic appeal make it ideal for everything from kitchen appliances to heavy-duty construction and medical devices. However, not all stainless steel is created equal. Different types of stainless steel are formulated for specific applications, and understanding these differences is essential for selecting the right material for your project.

In this article, we’ll explore the main types of stainless steel and their industrial uses, so you can make informed decisions in your next engineering, manufacturing, or construction endeavor.

Read more about: Why Stainless Steel Kitchen Sets Are Trending This Year

What Is Stainless Steel?

Stainless steel is an alloy primarily made from iron and chromium. The chromium content—usually at least 10.5%—forms a passive layer of chromium oxide on the surface, which prevents rust and corrosion. Depending on the composition and processing, stainless steel can be divided into several families, each with unique properties suited to specific applications.

The 5 Main Types of Stainless Steel

Stainless steel is generally categorized into five main types:

Austenitic Stainless Steel

Ferritic Stainless Steel

Martensitic Stainless Steel

Duplex Stainless Steel

Precipitation-Hardening Stainless Steel

Let’s explore each in more detail.

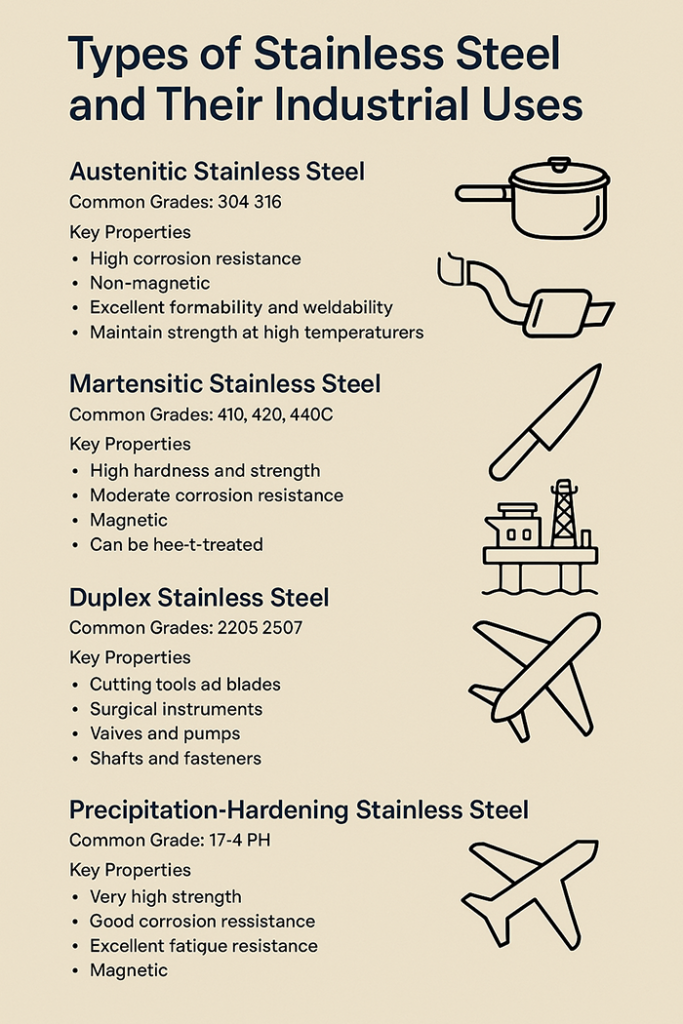

1. Austenitic Stainless Steel

Overview:

This is the most commonly used type of stainless steel, making up over 70% of global production. It has high levels of chromium and nickel, which contribute to its excellent corrosion resistance and non-magnetic properties.

Common Grades: 304, 316

Key Properties:

High corrosion resistance

Non-magnetic

Excellent formability and weldability

Can maintain strength at high temperatures

Industrial Uses:

Food and beverage processing equipment

Pharmaceutical and chemical equipment

Kitchen appliances and sinks

Marine applications (especially 316 grade)

Fun Fact:

Grade 316 is often referred to as “marine grade” stainless steel due to its high resistance to saltwater corrosion.

2. Ferritic Stainless Steel

Overview:

Ferritic stainless steels contain chromium but little to no nickel, making them more cost-effective than austenitic grades. They are magnetic and have good corrosion resistance, though generally not as high as austenitic types.

Common Grades: 409, 430

Key Properties:

Good corrosion resistance (especially against stress corrosion cracking)

Magnetic

Lower cost than austenitic steel

Limited weldability

Industrial Uses:

Automotive exhaust systems

Home appliances (e.g., dishwashers, ovens)

Architecture and decorative applications

Industrial roofing and cladding

3. Martensitic Stainless Steel

Overview:

Martensitic stainless steels are high in carbon and moderately high in chromium. They can be hardened through heat treatment, making them suitable for applications requiring strength and wear resistance.

Common Grades: 410, 420, 440C

Key Properties:

High hardness and strength

Moderate corrosion resistance

Magnetic

Can be heat-treated

Industrial Uses:

Cutting tools and blades

Surgical instruments

Valves and pumps

Shafts and fasteners

Note:

Because of their hardness, martensitic grades are ideal for products that experience frequent friction or impact.

4. Duplex Stainless Steel

Overview:

Duplex stainless steels are a hybrid of austenitic and ferritic structures. They offer a balance of strength, toughness, and corrosion resistance, often outperforming either group alone.

Common Grades: 2205, 2507

Key Properties:

High strength (up to twice that of austenitic stainless steel)

Excellent resistance to pitting and stress corrosion cracking

Magnetic

Good weldability

Industrial Uses:

Offshore oil and gas platforms

Chemical processing plants

Desalination equipment

Structural components in aggressive environments

Insight:

Duplex steels are increasingly chosen for high-pressure environments where both strength and resistance to aggressive corrosion are critical.

5. Precipitation-Hardening Stainless Steel (PH)

Overview:

These stainless steels are strengthened through a heat treatment process called precipitation hardening. They provide a combination of corrosion resistance and exceptional strength.

Common Grades: 17-4 PH (also known as Type 630)

Key Properties:

Very high strength

Good corrosion resistance

Excellent fatigue resistance

Magnetic

Industrial Uses:

Aerospace components

Nuclear reactors

Military weapons

High-performance machine parts

Fun Fact:

17-4 PH stainless steel is commonly used in the aerospace industry due to its excellent mechanical properties and corrosion resistance.

How to Choose the Right Type of Stainless Steel

Choosing the appropriate type of stainless steel for your application involves considering several factors:

Corrosion resistance: Will the product be exposed to moisture, chemicals, or salt?

Mechanical strength: Does it need to handle heavy loads or high pressure?

Magnetic properties: Is magnetism an issue in your application?

Cost-effectiveness: Can you compromise on performance for budget?

Weldability and formability: Will the steel be shaped or welded?

Austenitic types are the most general-purpose, while ferritic offers cost advantages. Duplex grades balance strength and corrosion resistance, while martensitic and PH types are ideal for high-stress, wear-resistant applications.

Understanding the types of stainless steel and their industrial uses is crucial for manufacturers, engineers, and project managers alike. Whether you’re designing kitchen equipment, marine structures, or aerospace components, choosing the right stainless steel can impact the safety, longevity, and success of your product.

As stainless steel continues to evolve with advanced metallurgical techniques, industries benefit from new possibilities in durability, sustainability, and performance. With the right choice, stainless steel becomes not just a material—but a foundation for innovation.

Check out also: 10 Minimalist Stainless Steel Fence Designs for Your Home